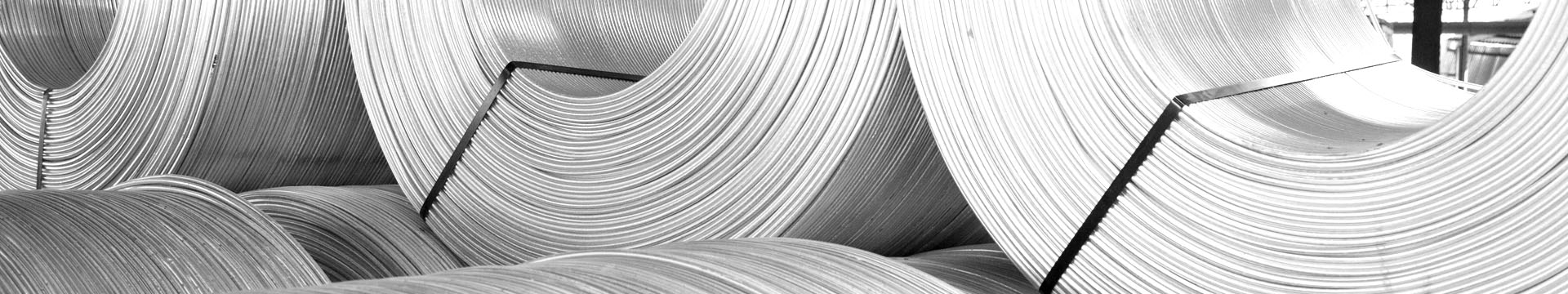

ALLOY WIRE RODS

• These are used for redrawing into Wires for manufacture of all aluminium Alloy Conductors (AAAC). Due to various advantages AAAC is replacing conventional ACSR/AAC.

| SPECIFICATIONS | |||||||||||||||||||||||

| 1. Diameter : | 9.5 mm +/- 0.5 mm | 7.6 mm +/- 0.5 mm T4 grade Rod. | ||||||||||||||||||||||

| 2. Quality : | Alloy AA 6201 equivalent to IS 64401 as per IS 9997 having following chemical composition. | ||||||||||||||||||||||

|

|||||||||||||||||||||||

| 3. Mechanical properties : | |||||||||||||||||||||||

| Tensile Strength : | 15 to 20 Kg/mm2 | ||||||||||||||||||||||

| Elongation | 7 to 11% on 250 Gauge Length | ||||||||||||||||||||||

| 4. Electrical properties : | |||||||||||||||||||||||

| Conductivity : | 54 to 56% IACS | ||||||||||||||||||||||

| 5. Coil Weight : | Varies between 1000 to 2000 Kgs. | ||||||||||||||||||||||

Wire Rods

Conductors

Others

Our Clients

Our Business

Copyright © 2016 Associated Group